FRN

|

|

|

|

|

|

|

|

| |

| |

"FR-N" MELT BLOWN CARTRIDGES

GENERAL FEATURES

The cartridges FR-N Series are designed to obtain a high

efficiency and filtration of various liquids having impurity. Using

only 100% pure polypropylene they are manufactured through

state of the art technology. They are generally used in

applications that require extremely high quality filtration. During

the manufacturing process, the polypropylene is mixed with

compressed hot air. Then it is stratified on a rigid polypropylene

core through a continues and constant rotating movement.

This process infuses and intersects the polypropylene fibres

amongst them selves. This creates the so called “Depth

Cartridge” guaranteeing a uniform filtration along all the

surface of the cartridge. The Polypropylene fibres used are

always and only of first choice which processed at high

temperatures welds them together eliminating any possibility

of losing particles or residuals. The range vary from 1 to 90

micron and standard lengths are 9”3/4 to 40”. The cartridges

are made up as one whole piece no matter what length.

TECHNICAL SHEET:

- Maximum operating temperature: ___________________ 80° C

- Maximum operation forward pressure: ____________ 6 bar 20°

- Recommended replaceable pressure drop: _________ 0,8 bar

- Efficiency: _____________________________________________ 95%

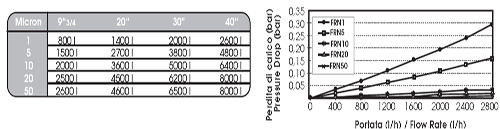

- Flow Rate: ______________________________________ see diagram |

|

| |

| |

|

|

|

| |

|

| Back To Fittering Cartride |

|

|

|