EDI

|

|

|

|

|

|

|

|

| |

| |

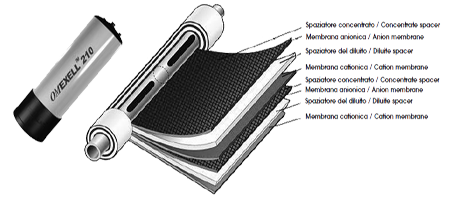

EDI OMEXELL

Electrodeionization or EDI, is a continuous and chemicalfree

process of removing ionized and ionisable species

from the feed water using DC power. EDI is typically used

to polish reverse osmosis (RO) permeate and to replace

conventional mixed bed ion exchange by eliminating

the need to store and handle hazardous chemicals used

for resin regeneration and associated waste neutralization

requirements. The patented OMEXELL™ EDI module

utilizes a spiral wound membrane (see figure below)

and ion exchange resins, sealed in a high strength (FRP)

pressure vessel. OMEXELL EDI optimizes performance,

maintains continuous product quality and can produce

up to 18 MW-cm high-purity water with high silica and

boron rejection. OMEXELL EDI is the first truly cost-effective

alternative to post-RO deionization applications. |

|

| |

| |

|

|

|

| |

| |

|

OMEXELL SPIRAL WOUND EDI ADVANTAGES

High Hardness Tolerance:

The patented concentrate flow design of the OMEXELL™ EDI

moduleis unlike that of the co-current flow design used in

conventional plate and frame EDI devices. This unique flow

design makes the OMEXELL EDI modules much more resistant

to hardness scaling allowing for higher hardness concentrations

of the feed water (up to 2 ppm as CaCO3) and reducing capital |

|

|

|

|

|

| |

|

| Back To Electrodeionization |

|

|

|